概述

The continuous casting vibration type ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection.

The LAG-S200 continuous casting ladle slag automatic detection system is developed by Wuhan CenterRise M&C Engineering Co., Ltd. after many years of research with many scientific research institutes, and fully combined with the actual situation on site. It has a real field application value as a continuous casting ladle slag automatic detection system.

The meaning of the system

1. Reduce the amount of tundish slag

2. Improve the purity of molten steel

3. Improve the life of the tundish

4. Reduce sliding nozzle erosion

5. Reduce nozzle blockage

6. Increase continuous pouring heats

7. Reduce the amount of residual steel in the ladle when high-quality steel is casting

8. Improve the yield of molten steel

9. Improve the quality of continuous casting billets

In order to improve the purity of the molten steel in the tundish, and improve the quality of the casting billet, especially to improve the quality of the billet in the transition section, and reduce the amount of residual steel in the high-quality ladle, and prolong the life of the tundish lining, and increase the continuous casting heats, it’s necessary to detect and control the slag in the later stage of continuous casting ladle casting.

The working principle

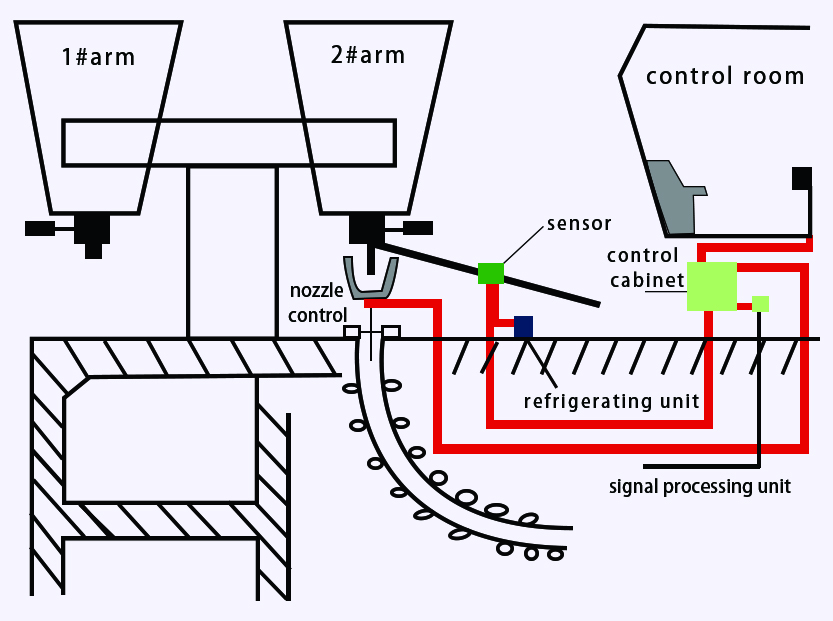

The LAG-S200 continuous casting ladle slag automatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through the long nozzle and pours into the tundish, the molten steel impacts the wall of the long nozzle and causes the vibration of the mechanical operating arm used to support the long nozzle. Since the specific gravity of the steelmaking slag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmaking slag appears when the molten steel is about to be all poured. At this time, due to the high viscosity and poor fluidity of light steelmaking slag, the impact force of the mixed flow of molten steel and steel slag on the wall of the long nozzle is quite different from that of pure molten steel. The system mainly monitors the ladle slag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm.

振动信号通过安装在操作杆中部的传感器,经前级调理放大模块接入系统控制柜的运行控制单元,经过处理后输出到工控机进行运算分析,系统检测到的下渣信号由系统控制柜输出到前端控制单元,进而控制报警喇叭、报警灯工作,或者发出关闭钢包水口的指令。

系统特点

(1)安装方便,基本不需对现场设备进行改造,安装调试工作不会影响企业的正常生产。

(2)检测精度高,有效率≥95%,渣量阈值设定准确,输出控制功能强大,在传感器寿命、传感器使用次数等技术指标上表现优异。

(3)传感器安装在远离钢水位置,采用专用制冷装置24小时冷却,外层采用复合防护结构,使用寿命长。

(4)采用专业化、针对性的信号处理方法,获取钢包下渣振动特征参数,通过振动信号数据库,分析、推理、判断有效下渣信号,下渣报警准确率高。

(5)架构建立基于人工智能网络,具有自学习、自感应的功能。

(6)设备采用模块化设计,各模块发生故障不会影响其它部分,保证系统运行更加可靠,维护更加方便。

(7)现场采用报警显示装置直观显示钢水及炉渣的流动状态,当发生炉渣夹带时,可选择自动或手动方式,在两种方式下,系统均会发出声光报警信号,提醒现场操作人员。

(8)系统具有强大的数据库功能,包括最近两包浇注时间记录的比对功能,系统自动存储运行数据,并每天生成记录文件。

(9)系统具备钢包水口自动控制功能,控制装置为系统的辅助系统,与钢包下渣检测系统联网,自动控制钢包水口的开启,实现中间包钢水液位的全过程控制。

系统组成

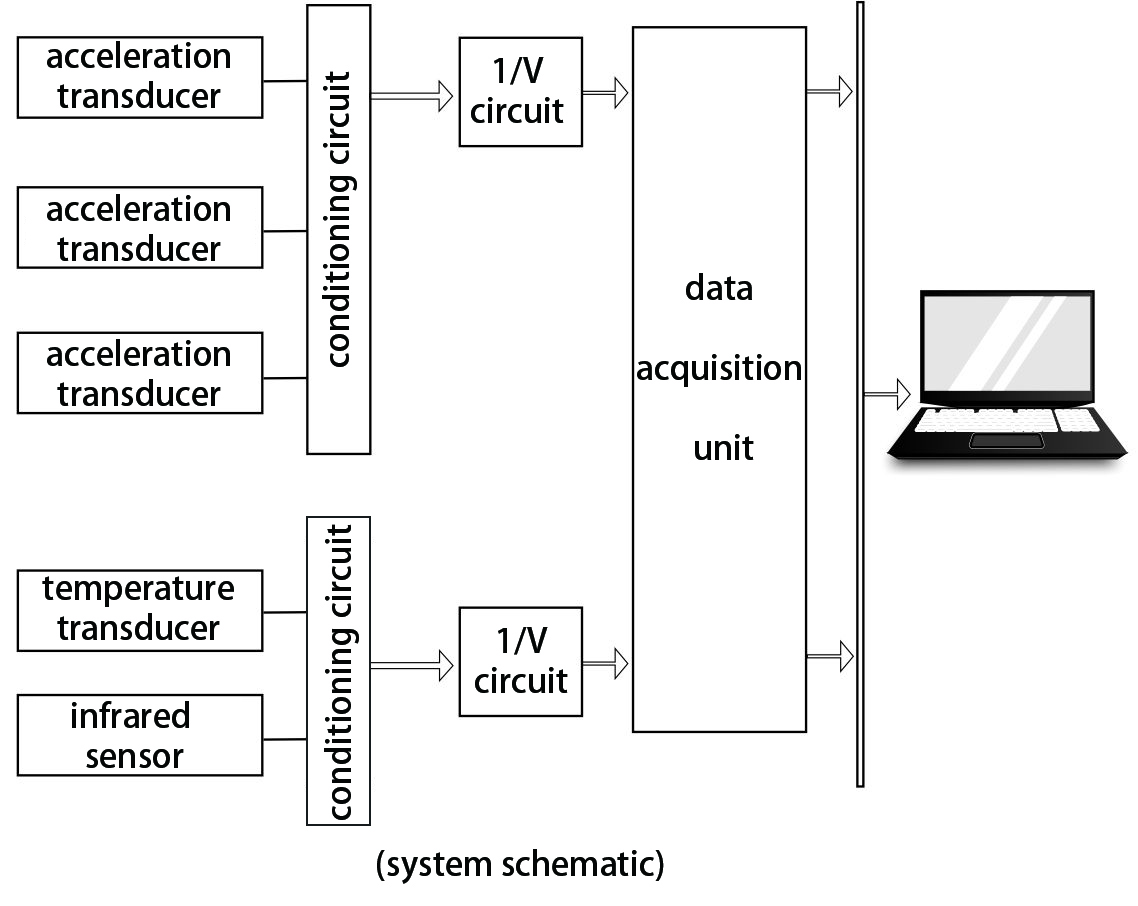

LAG-S200下渣检测系统由:振动检测传感器、前置信号放大器、下渣检测操作单元、中间包液位控制单元、现场操作指示箱、过程控制柜组成。

1、振动检测传感器:安装在塞棒机械臂上,检测钢包全浇铸过程的振动信号。

2、前置信号放大器:将振动检测传感器检测到的微弱振动信号进行放大、转换和传输。

3、下渣检测操作单元:对振动信号进行分析、判断、判别,实现全钢、混渣、全渣的判别,并输出下渣报警信号。

4、中间包液位控制单元:接受中间包喷嘴、钢包喷嘴的控制信号,根据需要实现对钢包下渣的自动或手动控制。

5、现场操作指示箱:提供掉渣报警指示、故障指示、系统启动方式选择、控制方式选择的人机交换。

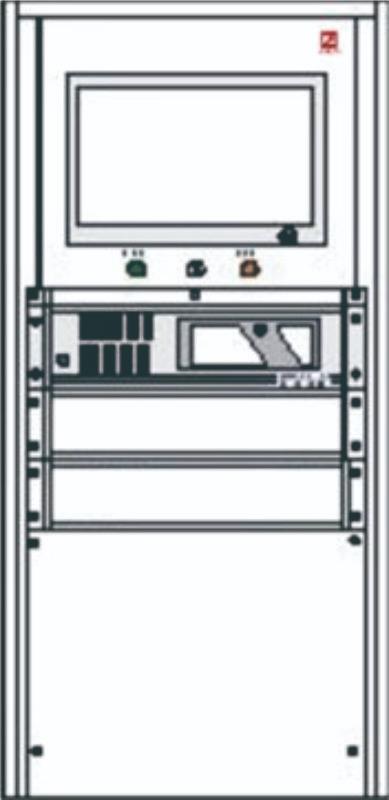

6.过程控制柜,提供电源管理、显示人机界面及设定管理。

系统参数

1、系统高精度控制钢水夹渣,实时关闭水口。

2、提高钢材质量,减少不良品,提高成品率。

3、钢水收得率提高0.3%-0.5%,喷嘴可自动关闭,克服了人工反应不及时的缺点,包内钢水残留量少,钢水阈值(渣阈值)由用户在较大范围内设定。

4.不涉及人为因素,可靠性高,具有良好的重复性或一致性。

5、炼钢渣不穿过或很少流入中间包,增加了耐火材料和滑动水口的使用寿命。

6、减少中间包水口堵塞,增加中间包连续浇注次数。